Are you facing challenges with moisture damage and reduced lifespan in your self-leveling compound applications? Then Silicone Hydrophobic Powder (SHP) might be exactly what you need to significantly improve your formulations. As ZOVAE, we understand the critical role of high-performance materials in construction, and our SHP is designed to deliver exactly that.

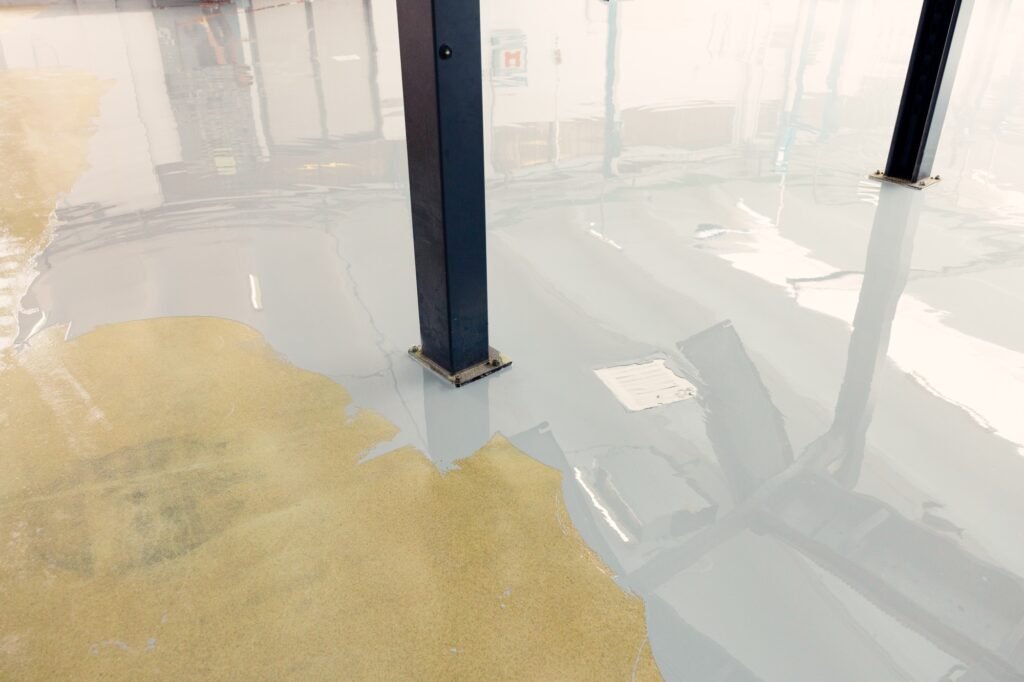

Silicone Hydrophobic Powder is a specially designed additive that transforms ordinary self-leveling compounds into high-performance, water-resistant materials. Think of it as a raincoat for your concrete – it creates a barrier that repels water and protects against the damaging effects of moisture. Essentially, it’s a fine, free-flowing powder composed of modified silane/siloxane polymers that, when mixed into cement-based mixtures, imparts a remarkable hydrophobic effect. This effect is achieved through the chemical bonding of the silicone polymers with the cement matrix, creating a durable and long-lasting water-repellent surface.

Imagine tiny umbrellas dispersed throughout your self-leveling compound. That's essentially how SHP works!

The SHP is thoroughly mixed into the dry self-leveling compound mixture. Its fine particle size ensures even distribution.

When water is added to the mixture, the SHP doesn't dissolve. Instead, it remains as discrete particles.

As the cement hydrates and hardens, the modified silane/siloxane polymers in the SHP react with the cement components, forming a chemically bonded hydrophobic layer. This layer lines the pores and capillaries within the concrete matrix.

This hydrophobic layer prevents water from penetrating the concrete, effectively reducing water absorption and minimizing the risk of moisture-related damage such as cracking, efflorescence, and freeze-thaw damage.

By reducing water penetration, SHP also helps to prevent the leaching of soluble salts from the concrete, which can weaken the structure over time. This contributes to the overall durability and lifespan of the self-leveling compound.

The strong chemical bonds between the SHP and the cement matrix ensure that the hydrophobic effect remains stable and effective over time, providing long-lasting protection against water damage.

In essence, SHP acts as a microscopic army of water-repellent agents, safeguarding your self-leveling compound from the harmful effects of moisture.

Silicone Hydrophobic Powder can be effectively used in various types and grades of self-leveling compounds, significantly enhancing their performance.

Using Silicone Hydrophobic Powder for self-leveling compounds, offers significant advantages. Here’s a breakdown of the key benefits you can expect:

As ZOVAE, we offer a range of high-quality Silicone Hydrophobic Powders specifically formulated for self-leveling compounds. Our ZOVAE SHP series ensures consistent performance, superior water repellency, and enhanced durability. We understand that choosing the right product is vital to your project success.

| Property | ZOVAE SHP 50 |

|---|---|

| Appearance | Fine, free-flowing white powder |

| Active Ingredient | Modified Silane Polymer |

| pH (10% Aqueous Solution) | 7.0 - 8.5 |

| Usage Range | 0.1% - 0.5% by weight of cementitious material |

| Key Features | Excellent water repellency, good dispersibility |

| Recommended For | Standard to Enhanced Grade Self-Leveling Compounds |

ZOVAE is committed to providing not only superior products but also comprehensive support:

Selecting the appropriate SHP depends on various factors, including the intended application environment, desired performance level, and budgetary constraints. Understanding these factors can guide you to the most effective solution.

Consider the following factors when choosing an SHP:

Key to Success: Ensure thorough mixing of the SHP into the dry mix to achieve optimal water repellency and durability.

| Item | Details | Item | Details |

|---|---|---|---|

| MOQ | 25 kg | Packaging | 25 kg bags, 500 kg jumbo bags |

| Lead Time | 7-14 days | Payment Terms | T/T, L/C |

| Shipping Options | Sea, Air, Land | Sample Policy | Free samples available upon request |

As ZOVAE, we are equipped with state-of-the-art manufacturing facilities and a dedicated R&D team focused on developing innovative solutions for the construction industry. Our quality control processes adhere to the highest industry standards, ensuring consistent product performance and reliability. We are continuously investing in research and development to improve our products and meet the evolving needs of our customers. Our equipment includes advanced particle size analyzers, hydrophobicity testers, and cement hydration monitoring systems, ensuring that every batch of ZOVAE SHP meets our stringent quality criteria.

We are also pioneering the use of bio-based silane/siloxane polymers in our SHP formulations, contributing to a more sustainable construction industry. This commitment to innovation ensures our Silicone Hydrophobic Powder for self-leveling compounds remains at the forefront of the industry.

Contact ZOVAE today and request a free sample of our Silicone Hydrophobic Powder to experience the difference firsthand. Elevate your projects with enhanced durability, superior water resistance, and lasting performance. Let ZOVAE be your partner in building a better, more resilient future. We are confident that our Silicone Hydrophobic Powder will significantly improve your self-leveling compound formulations. Click here to request your free sample now!

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.