Redispersible Polymer Powder (RDP), is a water-soluble polymer powder that transforms into a liquid emulsion when mixed with water, mirroring the original polymer dispersion. Think of it as a powdered adhesive that "comes back to life" upon hydration.

In the context of repair mortar, RDP functions as a vital binding agent and performance enhancer. It substantially boosts the mortar's capacity to resist water penetration, firmly adhere to various surfaces, and endure structural stresses. Ultimately, it is a key ingredient in achieving repairs that are both durable and long-lasting, especially in moisture-prone environments.

Imagine a concrete surface riddled with microscopic cracks and pores, creating pathways for water to infiltrate and cause damage. Traditional repair mortars often struggle to effectively fill these tiny gaps and lack the flexibility to accommodate movement, leading to recurring cracks. RDP addresses these problems through a multi-stage process:

RDP-modified repair mortars can be customized to meet specific application needs by adjusting the type and dosage of RPP used. Here’s a breakdown of common grades, helping you choose the correct RDP grade for your repair mortar:

RDP-modified repair mortars can be customized to meet specific application needs by adjusting the type and dosage of RDP used. Here’s a breakdown of common grades, helping you choose the correct RDP grade for your repair mortar:

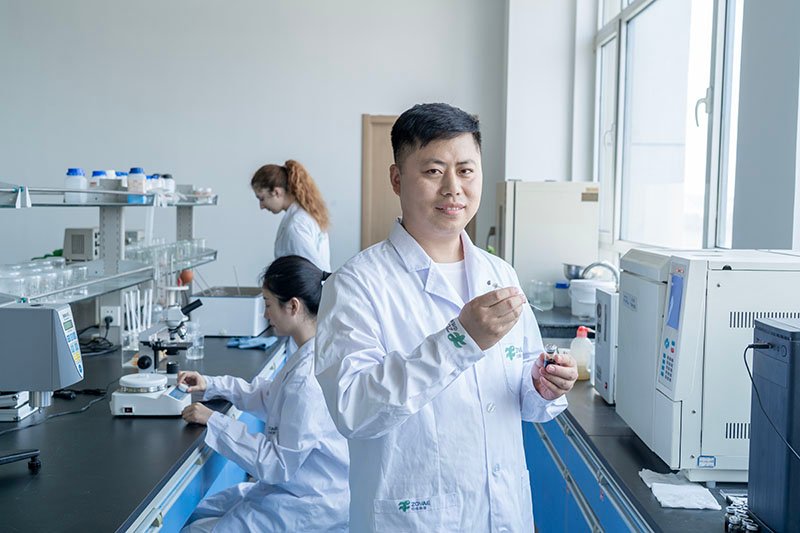

As ZOVAE, we are a leading manufacturer of high-quality Redispersible Polymer Powders, specifically designed to boost the performance of repair mortars. Our ZOVAE series offers a comprehensive range of RDP grades tailored to meet the diverse requirements of the construction industry.

| Parameter | ZOVAE Rigid RDP | ZOVAE Flexible RDP | ZOVAE Semi-Flexible RDP | ZOVAE Hydrophobic RDP | ZOVAE Self-Leveling RDP |

|---|---|---|---|---|---|

| Product Number | ZW5018N, ZW5115N, ZW6011N | ZW6045N, ZW6048N | ZW5026N, ZW6028N | ZW9032H, ZW9035H | ZW6111L |

| Solid Content % | ≧98% | ≧98% | ≧98% | ≧98% | ≧98% |

| pH | / | 5.0-8.0 | 5.0-8.0 | 7.0-9.0 | 5.0-8.0 |

| Particle Size | ~80μm | ~80μm | ~80μm | ~80μm | ~80μm |

| Bulk Density | 500-600 g/L | 500-600 g/L | 500-600 g/L | 450-550 g/L | 450-550 g/L |

Selecting the right RDP grade is essential for achieving optimal performance in your repair mortar. Consider these factors when choosing:

| Condition | Recommendation |

|---|---|

| Dry Interior Environment | ZOVAE ZW5026N (for general improvements in workability and adhesion) |

| Damp Exterior Environment | ZOVAE ZW9032H (for enhanced flexibility and water resistance) |

| Harsh Marine Environment | ZOVAE ZW9035H (for superior waterproofing, alkali resistance, and long-term durability) |

| Large Crack Repair | ZOVAE ZW6045N (due to its enhanced flexibility) |

| Thin Layer Application | ZOVAE ZW6028N (promotes good adhesion on thin applications) |

| Problem | Solution |

|---|---|

| Premature Cracking | Problem: Mortar cracks due to shrinkage or substrate movement. Solution: Incorporate ZOVAE ZW6045N to enhance flexibility. |

| Poor Adhesion to Existing Concrete | Problem: Mortar fails to bond properly, leading to delamination. Solution: Use ZOVAE ZW6028N to improve adhesion to the substrate. |

| Water Ingress and Damage | Problem: Water penetrates the mortar, causing freeze-thaw damage and corrosion. Solution: Utilize ZOVAE ZW9035H for superior waterproofing. |

Success Key: Ensure thorough mixing to fully redisperse the RDP and achieve optimal performance. Always consult the product’s technical data sheet (TDS) for specific recommendations.

| Item | Specification |

|---|---|

| Packaging | 25 kg multi-layer paper bags with PE liner |

| MOQ | 1000 kg |

| Lead Time | 7-14 days |

| Payment Terms | T/T, L/C |

| Shipping | Sea freight, air freight, or land transportation |

| Sample Policy | Free samples available upon request |

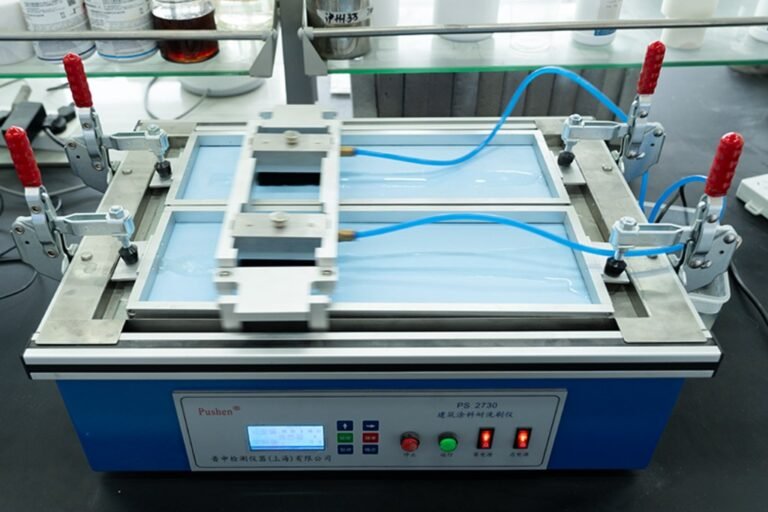

As ZOVAE, our state-of-the-art manufacturing facility is equipped with advanced process control systems to ensure consistent product quality. We adhere to the highest international standards, and our dedicated R&D team is constantly innovating to develop new and improved RDP solutions for the construction industry. We employ advanced techniques such as:

Incorporating Redispersible Polymer Powder into your repair mortar formulations is a proven method to enhance performance, improve durability, and extend the lifespan of your repair projects. With ZOVAE RDPs, you can achieve superior waterproofing, adhesion, flexibility, and workability, ensuring lasting results and satisfied customers.

Contact ZOVAE today to request a free sample, discuss your specific requirements, and discover how our RDP solutions can elevate your repair mortar to the next level. Improve your repair mortar performance – contact us now!

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.