Are you looking for ways to make your wall putty applications smoother, stronger, and longer-lasting? Then Redispersible Polymer Powder (RDP) might be exactly what you need. As ZOVAE, a leading provider of RDP solutions, I’m here to share my expertise on how RDP can transform your wall putty formulations.

Redispersible Polymer Powder (RDP) is essentially a dry, free-flowing powder created from polymer emulsions, typically through a spray-drying process. Imagine taking a liquid glue (the polymer emulsion) and turning it into a powder that can be easily mixed into dry building materials.

When water is added, this powder “redisperses,” meaning it turns back into a stable emulsion, acting like a glue within the wall putty. Think of it as a dormant superhero waiting to be activated by water to unleash its binding and strengthening powers! It’s primarily based on ethylene-vinyl acetate (EVA) copolymers, offering a great balance of flexibility and adhesion.

Let’s break down how RDP works its magic in wall putty:

In simpler terms, RDP acts like tiny threads of flexible glue that weave throughout the wall putty, binding everything together and preventing it from cracking under stress. This process ensures a smoother, more durable finish.

RDP is utilized across different grades of wall putty to enhance specific properties, adapting to varied application needs:

As ZOVAE, we offer a range of Redispersible Polymer Powders specifically designed for wall putty applications. Our products are manufactured using advanced spray-drying technology and high-quality raw materials to ensure consistent performance and reliability. Our RDP solutions are developed in collaboration with leading polymer scientists like Dr. Anya Sharma, whose research on polymer film formation has been instrumental in improving RDP performance.

| Product Model | Bulk Density (kg/m³) | Ash Content (at 1000℃) | MFFT (℃) | Key Features for Wall Putty | Recommended Reasons |

|---|---|---|---|---|---|

| ZOVAE®5026N | 500-600 | 13±2% | 1 | Enhances adhesion, flexibility, workability, water resistance | General-purpose with medium flexibility; suitable for low-emission, high-strength mortars |

| ZOVAE®5115N | 500-600 | 13±2% | 4 | Enhances adhesion, flexibility, workability, water resistance | Rigid copolymer base; ideal for versatile dry-mix mortars with strong bonding |

| ZOVAE®6045N | 500-600 | 12±2% | 0 | Enhances adhesion, flexibility, workability, water resistance | Excellent flexibility; minimal impact on flowability and thixotropy |

Selecting the appropriate RDP grade is crucial for achieving the desired performance characteristics in your wall putty. Consider the following factors:

| Condition | Recommended RDP Grade | Key Benefits |

|---|---|---|

| Interior Walls, Standard Finish | ZOVAE® 6011N | Excellent Adhesion, Workability |

| High Humidity Environments | ZOVAE® 9032H | Superior Crack Resistance, Water Repellency |

| Cost-Effective Formulation | ZOVAE® 5026N | Enhanced Water Retention, Economical Solution |

| Enhanced Crack Resistance Needed | ZOVAE® 6045N | Flexibility, Bridges Minor Imperfections |

| Problem | Solution |

|---|---|

| Wall putty cracks after application | Problem: Insufficient flexibility in the wall putty formulation. Solution: Increase the dosage of RDP or switch to a higher-performance RDP grade (e.g., ZW 6045N) with enhanced flexibility and crack resistance. |

| Poor adhesion to the substrate | Problem: Inadequate bonding between the wall putty and the substrate. Solution: Ensure proper surface preparation and use an RDP with excellent adhesion properties (e.g., ZW 6028N). Consider increasing the RDP dosage. |

| Wall putty dries too quickly | Problem: Rapid water loss leading to poor hydration and cracking. Solution: Use an RDP with enhanced water retention properties (e.g., ZW 6011N) to slow down the drying process and ensure proper hydration. |

Key Tip: Always follow the manufacturer's recommended dosage and mixing instructions for optimal performance. Overdosing can lead to reduced strength and increased costs.

| Details | Information |

|---|---|

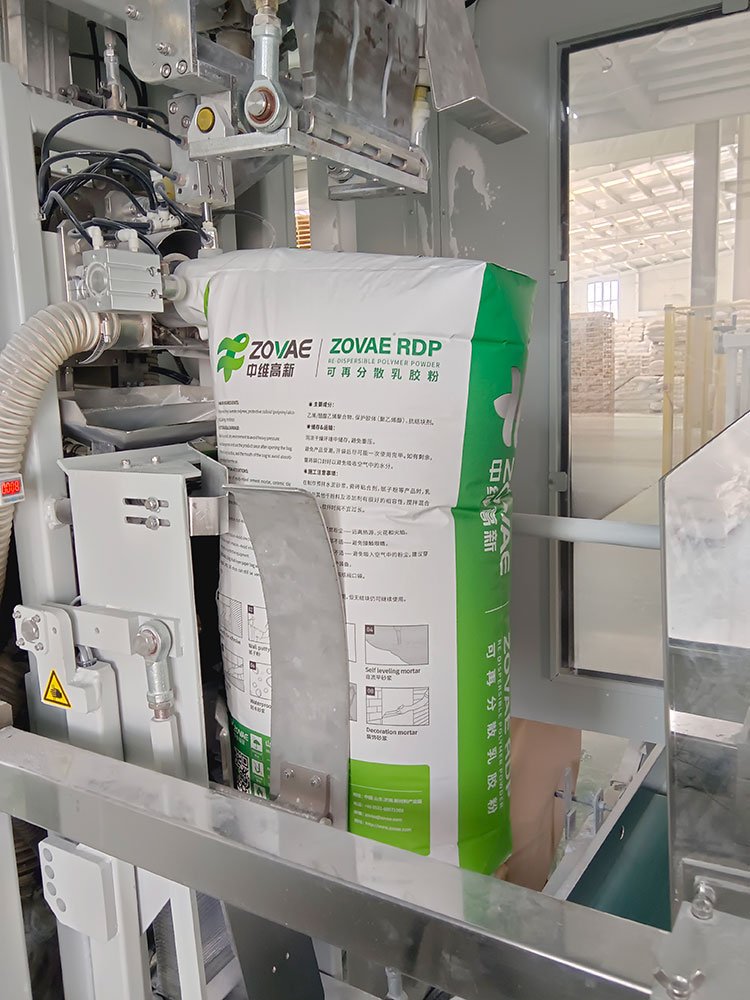

| Packaging | 25 kg multi-layer paper bags with polyethylene liner |

| MOQ | 1 Metric Ton |

| Lead Time | 7-14 days depending on order volume and destination |

| Payment Terms | T/T, L/C |

| Shipping Options | Sea freight, air freight, or land transportation |

| Sample Policy | Free samples (up to 500g) are available upon request. Contact our sales team to arrange for sample delivery. |

As ZOVAE, we are committed to providing high-quality RDP products that meet the stringent requirements of the construction industry. Our manufacturing facility is equipped with advanced spray-drying equipment and a comprehensive quality control system to ensure consistent product quality. We adhere to strict quality standards and conduct rigorous testing throughout the production process. We maintain certifications like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) to demonstrate our commitment to excellence.

Our R&D team is dedicated to developing innovative RDP solutions that address the evolving needs of our customers. We continuously invest in research and development to improve the performance and sustainability of our products. We provide custom formulation services, performance guarantees for qualified use, and on-site technical support to help you optimize your wall putty formulations. Our labs are equipped with state-of-the-art analytical equipment and our R&D team possesses extensive experience in polymer chemistry and construction materials. We actively participate in industry conferences to stay at the forefront of RDP technology.

Unlock the ZOVAE Experience Today! Discover why thousands trust ZOVAE's premium products. We offer global free services for all samples and provide free sample testing! Contact our team now to claim your complimentary sample kit and witness our innovative solutions.

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.