What is Redispersible Polymer Powder (RDP) for Tile Adhesive?

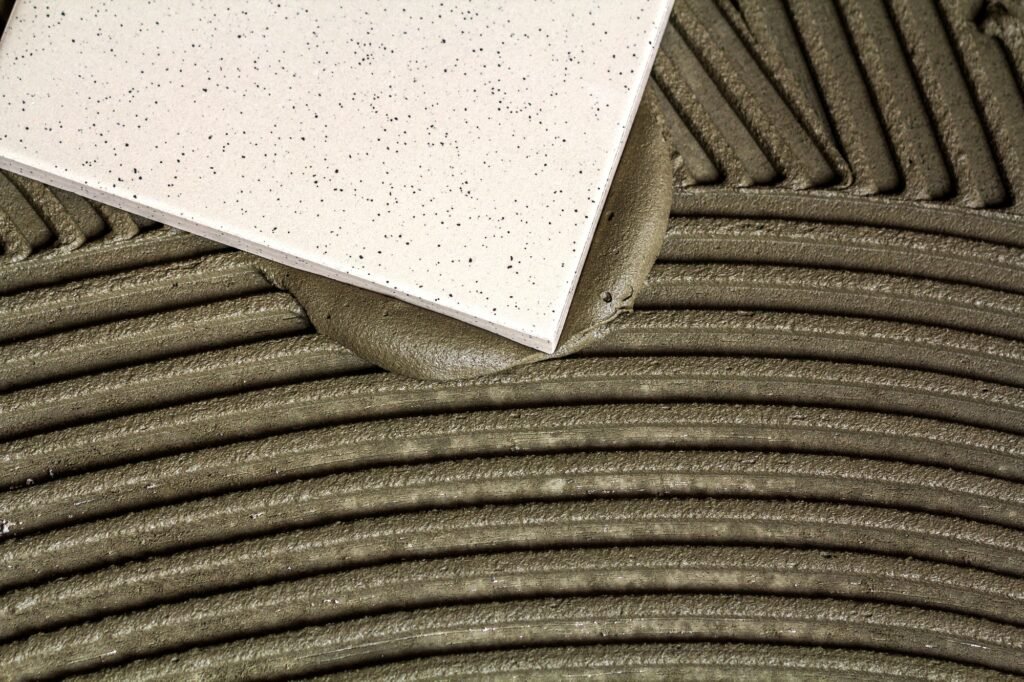

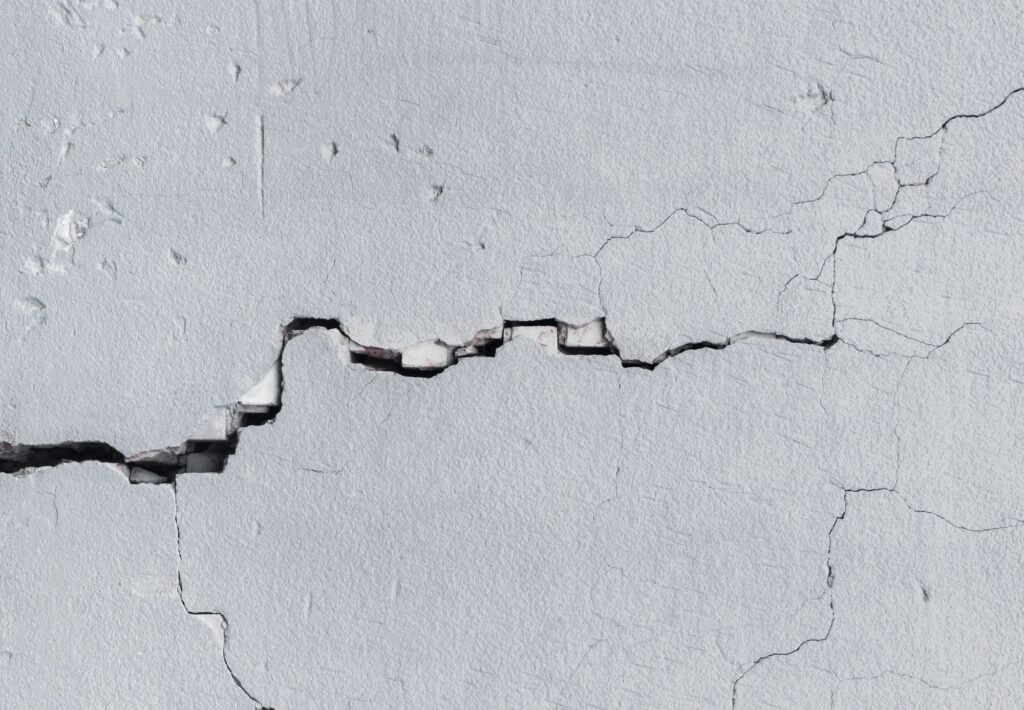

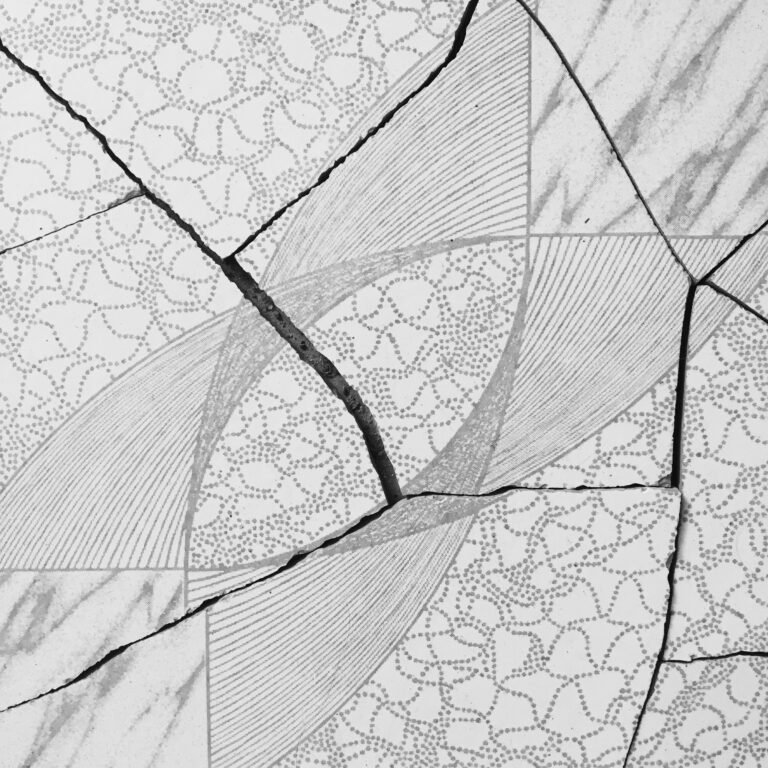

Imagine a network of tiny, flexible springs embedded within the adhesive matrix. When mixed with water, RDP redisperses into individual polymer particles. These particles then coalesce during the curing process, forming a continuous, flexible film. This film acts as a reinforcing web, distributing stress, absorbing movement, and providing a tenacious bond between the tile and the substrate. This is achieved through a complex process: