Are you facing challenges with the adhesion, flexibility, or water resistance of your gypsum plaster? Redispersible Polymer Powder (RDP) might be exactly what you need to overcome these issues and significantly improve the overall performance and lifespan of your gypsum-based products. As ZOVAE, a leading provider of RDP solutions, I’m here to share my expertise on how RDP works and why it’s a game-changer for gypsum plaster.

Redispersible Polymer Powder, often abbreviated as RDP, is a free-flowing, white powder derived from spray-drying polymer emulsions, typically vinyl acetate-ethylene (VAE) copolymers. Think of it as tiny, dormant droplets of polymer waiting to be awakened by water. When mixed with water, RDP transforms back into a stable emulsion, much like the original polymer dispersion. This redispersed emulsion acts as a powerful binder and modifier, dramatically enhancing the properties of cement-based and, crucially, gypsum-based dry mortars like plaster. RDP is like the secret ingredient that takes ordinary gypsum plaster to the next level.

Imagine gypsum plaster as a network of tiny particles. When water is added, these particles hydrate and begin to bind together. However, this inherent binding is often weak, leading to issues like cracking, poor adhesion, and susceptibility to moisture damage. This is where RDP steps in to play a crucial role. The addition of RDP enhances the overall performance of gypsum plaster, leading to more durable and reliable construction outcomes. Let's delve into the mechanism in more detail:

The RDP, initially in powder form, is thoroughly mixed with the dry gypsum plaster.

Upon the addition of water, the RDP particles redisperse, forming a stable polymer emulsion throughout the mixture. This process allows the polymer to evenly distribute within the gypsum matrix.

As the gypsum plaster hydrates and sets, the redispersed polymer particles coalesce and form a continuous polymer film. This film is critical for enhancing the physical properties of the plaster.

This polymer film acts as a bridge, bonding the gypsum particles together more strongly and also improving the adhesion of the plaster to the substrate (e.g., brick, concrete, or drywall). This improved adhesion is vital for long-lasting performance.

The polymer film also imparts flexibility to the plaster, allowing it to better withstand movement and stress without cracking. This flexibility helps the plaster adapt to environmental changes and structural shifts.

Certain RDPs are hydrophobic, meaning they repel water. This reduces the water absorption of the plaster, making it more resistant to moisture damage.

In essence, RDP acts as a microscopic reinforcement system within the gypsum plaster, providing superior adhesion, flexibility, and water resistance compared to unmodified plaster.

RDP is versatile and can be incorporated into various grades of gypsum plaster to enhance specific properties. Here's how it's used in different types:

The specific type and dosage of RDP will vary depending on the desired properties and the specific formulation of the gypsum plaster.

As ZOVAE, I've seen firsthand the transformative benefits of using RDP in gypsum plaster. Here's a summary of the key advantages:

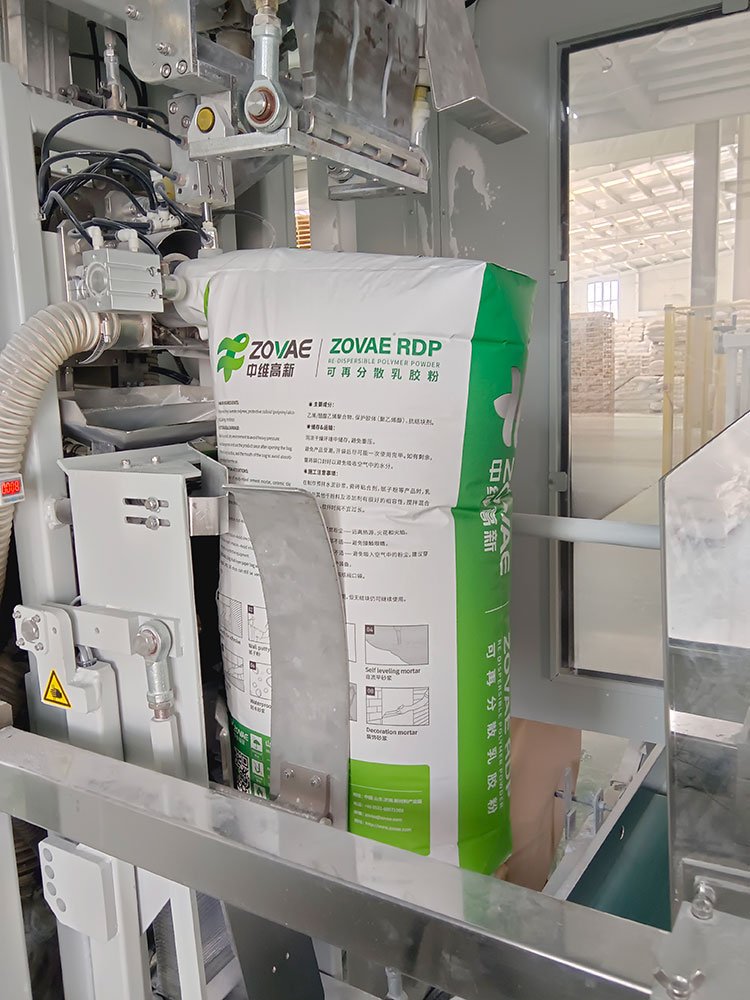

ZOVAE offers a comprehensive range of Redispersible Polymer Powders specifically formulated to enhance the performance of gypsum plaster. Our ZOVAE series are designed to deliver superior adhesion, flexibility, and water resistance, ensuring long-lasting and aesthetically pleasing results.

| Product Name | Polymer Type | Key Features | Recommended Applications |

|---|---|---|---|

| ZOVAE RDP 5018N | VAE (Vinyl Acetate Ethylene) | Excellent adhesion, good flexibility, improves workability | Standard gypsum plaster, joint compounds, interior finishes |

| ZOVAE RDP 6111L | VAE (Vinyl Acetate Ethylene) | Enhanced water resistance, high flexural strength, reduced cracking | High-performance gypsum plaster, bathrooms, kitchens, areas with high humidity |

| ZOVAE RDP 9032H | VAE (Vinyl Acetate Ethylene) | Superior adhesion to challenging substrates, excellent sag resistance, improved open time | Lightweight gypsum plaster, repairs, applications over difficult surfaces |

Here's why I believe ZOVAE's RDP is the best choice for your gypsum plaster:

| Problem | Solution with ZOVAE RDP |

|---|---|

| Cracking in Gypsum Plaster | Incorporate ZOVAE RDP 6045N to improve flexibility and reduce shrinkage, allowing the plaster to better accommodate movement and stress. |

| Poor Adhesion to Substrate | Use ZOVAE RDP 6028N to enhance bond strength to a wide range of substrates, ensuring a strong and durable connection. |

| Moisture Damage and Efflorescence | Add ZOVAE RDP 6111L, which enhances the water resistance and lowers the likelihood of moisture damage and the appearance of efflorescence, enhancing the plaster's longevity in humid environments. |

Key Success Suggestion: Ensure the RDP is evenly dispersed throughout the plaster mixture for optimal performance.

| Item | Details |

|---|---|

| Packaging | 25 kg bags |

| MOQ | 1 ton |

| Lead Time | 7-14 days |

| Payment Terms | T/T, L/C |

| Shipping Options | Sea, Air, Land |

| Sample Policy | Free samples available; contact us for details. |

ZOVAE is committed to providing high-quality RDP products. Our state-of-the-art manufacturing facilities are equipped with advanced process control systems to ensure consistent quality. We adhere to strict quality standards throughout the entire production process, from raw material sourcing to final product packaging.

Our R&D team is dedicated to developing innovative RDP solutions to meet the evolving needs of the construction industry. We continuously invest in research and development to improve the performance, sustainability, and cost-effectiveness of our products. Our areas of focus include developing new polymer chemistries, improving RDP redispersibility, and enhancing the compatibility of RDP with various building materials.

Contact ZOVAE today and get your free sample of ZOVAE RDP! See how our Redispersible Polymer Powder can dramatically improve the adhesion, flexibility, and water resistance of your gypsum plaster. Don’t settle for less – choose ZOVAE for superior performance and lasting results! Improve your Wall Putties, Joint Compounds, Interior Finishes and Repair Mortars with our cost effective RDP solution today.

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.