Are you facing challenges with cracking, poor adhesion, or water intrusion in your EIFS (Exterior Insulation and Finish System)? These issues can lead to costly repairs, reduced energy efficiency, and a compromised aesthetic appeal. As ZOVAE, I understand these concerns deeply. That’s why I want to share how Redispersible Polymer Powder (RDP) offers a powerful solution, significantly improving the performance and longevity of EIFS systems.

Redispersible Polymer Powder is a dry, free-flowing powder created by spray-drying polymer emulsions. Think of it as taking a liquid latex paint and transforming it into a powder that can be easily mixed into dry mortars. When mixed with water, this powder redisperses, recreating a stable polymer emulsion within the mortar matrix.

I like to think of it as adding a microscopic, flexible network that strengthens and enhances the properties of the cement or gypsum-based materials used in EIFS. This is crucial for preventing common issues like cracking.

The real magic of RDP lies in its ability to integrate into the EIFS matrix at a microscopic level. Here's how it works:

Essentially, RDP acts as both a microscopic "glue" and a flexible reinforcing agent within the EIFS, directly addressing many common performance issues that EIFS systems face. It’s like having a network of tiny shock absorbers within your walls. The demand for RDP in construction is expected to grow significantly due to its performance benefits.

I’ve seen RDP used across various EIFS components, each application benefiting in unique ways:

Primarily used in the adhesive mortar to improve the bond between the insulation board (EPS or mineral wool) and the substrate. It also enhances the flexibility and crack resistance of the base coat.

In Polymer-Based (PB) and Polymer-Modified (PM) EIFS, RDP plays a crucial role. PB EIFS relies heavily on the polymer for its flexibility and impact resistance, with RDP significantly contributing to both the adhesive and base coat performance.

High-performance EIFS systems, designed for demanding environments, utilize specialized RDP grades to achieve superior adhesion, flexibility, and water resistance. RDPs are often formulated with specific polymer chemistries to meet the system's rigorous requirements.

Here at ZOVAE, we believe in the power of RDP because we’ve seen the results firsthand. Here are just a few of the advantages it offers:

At ZOVAE, we’ve developed our ZOVAE RDP series, a range of high-quality RDP products specifically designed to optimize the performance of EIFS systems. Our products are formulated with advanced polymer technology to deliver superior adhesion, flexibility, and durability. To further showcase our authority and expertise, you may find helpful resources from the EIMA (EIFS Industry Members Association), a trusted source in our industry.

I encourage you to contact us for a free sample and let our technical experts help you select the optimal ZOVAE RDP grade for your specific EIFS application. We even offer custom formulations to meet your unique performance requirements. We can help determine the right formula for crack resistance, a key benefit of using our products.

| Product Name | Product Grades | Key Features | Typical Applications |

|---|---|---|---|

| ZOVAE Rigid RDP | ZW5018N ZW5115N ZW6011N | Excellent adhesion, good flexibility, cost-effective | EIFS adhesives, base coats for standard systems |

| ZOVAE Semi-flexible RDP | ZW5026N ZW6028N | Enhanced flexibility, improved water resistance, excellent crack bridging | EIFS base coats and finish coats for PM and high-performance systems |

| ZOVAE Flexible RDP | ZW6045N ZW6048N | Superior UV resistance, excellent long-term durability, ideal for demanding environments | EIFS finish coats for high-performance systems, particularly in coastal or high-altitude areas |

Choosing the correct RDP grade depends on several factors. Here's what I recommend considering:

Use this table as a quick guide to select the appropriate ZOVAE RDP grade:

| Condition | Recommendation | ZOVAE RDP Grade Recommendation |

|---|---|---|

| Standard EIFS, general climate | Good adhesion, cost-effective | ZW5018N, ZW5115N, ZW6011N |

| Modified EIFS, moderate climate | Enhanced flexibility, improved water resistance | ZW5026N, ZW6028N |

| High-Performance EIFS, harsh UV | Superior UV resistance, long-term durability | ZW6011N, ZW5026N, ZW6028N |

| Cold Climate, freeze-thaw cycle | Enhanced freeze-thaw resistance, good water resistance | ZW6045N, ZW6048N |

| Coastal Environment, high humidity | Excellent water resistance, good salt spray resistance | ZW9032H, ZW9035H |

Here are three common problems I've seen in EIFS applications, and how RDP can provide effective solutions:

To ensure the best possible results, keep these guidelines in mind:

| Detail | Information |

|---|---|

| Packaging | 25 kg bags, 500 kg big bags |

| Minimum Order Quantity (MOQ) | 1 ton |

| Lead Time | 7-14 days depending on order volume and product availability |

| Payment Terms | T/T, L/C |

| Shipping | Sea freight, air freight, or land transportation |

| Sample Policy | Free samples available upon request (shipping charges may apply) |

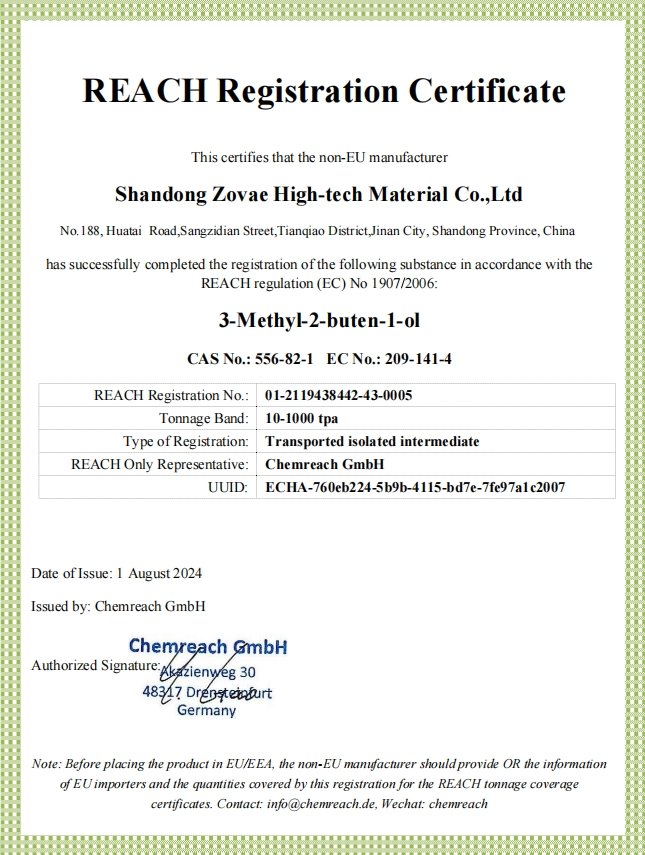

ZOVAE is committed to providing high-quality RDP products and exceptional technical support to our customers. Our state-of-the-art manufacturing facility is equipped with advanced spray-drying technology and adheres to strict quality control standards (REACH certified).

Our dedicated R&D team continuously develops innovative RDP formulations to meet the evolving needs of the construction industry. We invest heavily in research and development, focusing on improving the performance, durability, and sustainability of our products.

Our cutting-edge laboratory is equipped with advanced analytical instruments to ensure consistent quality and performance. We are committed to providing our customers with reliable and innovative RDP solutions.

Redispersible Polymer Powder is a vital ingredient for enhancing the performance and longevity of EIFS systems. ZOVAE's BondPlus series offers a comprehensive range of RDP solutions tailored to meet the specific needs of various EIFS applications. By incorporating ZOVAE RDP into your EIFS formulations, you can achieve superior adhesion, flexibility, crack resistance, and water resistance, resulting in a more durable, energy-efficient, and aesthetically pleasing building envelope.

Ready to improve your EIFS performance? Contact ZOVAE today to request a free sample of ZOVAE BondPlus RDP and discuss your specific project requirements. Our team of experts is here to help you find the perfect RDP solution for your needs! We believe that using the right RDP can truly transform the performance and lifespan of your EIFS system. Don't wait – reach out today and let's discuss how ZOVAE can help you achieve superior results. Learn more about our other solutions.

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.