Are you facing challenges with cracking, poor adhesion, or insufficient flow in your cement-based self-leveling compounds? Then Redispersible Polymer Powder (RDP) might be exactly what you need. These common issues can lead to costly repairs, dissatisfied clients, and ultimately, damage your reputation. Fortunately, RDP offers a powerful solution to these problems, improving not only the performance of your self-leveling compounds but also the overall quality and longevity of your flooring projects. As ZOVAE, a leading provider of RDP, I'm here to share my expertise on how our ZOVAE® RDP series can revolutionize your flooring applications.

Redispersible Polymer Powder, or RDP, is a water-soluble polymer powder obtained through the spray-drying of polymer emulsions. Imagine taking a high-quality liquid adhesive and transforming it into a fine, easily manageable powder. This powder, when mixed with water in cement-based formulations, redisperses to form a stable polymer emulsion, effectively re-creating the original adhesive properties. Think of it as a "dry glue" that reactivates upon contact with water, giving your self-leveling compound that extra edge in performance.

RDPs enhance the workability and durability of cement-based materials, which is a testament to their effectiveness.

Now, how does this "dry glue" work its magic in cement-based self-leveling compounds? The process can be understood through a series of steps: Firstly, the RDP is thoroughly mixed into the dry self-leveling compound. When water is added, the powder redisperses, forming a network of polymer chains within the cement matrix. This polymer network acts as a flexible bridge, improving the cohesion and adhesion between the cement particles and the substrate. By improving the flexibility, the RDP helps absorb stresses caused by movement and temperature changes, preventing cracks. The polymer film also reduces water absorption, improving the compound’s resistance to freeze-thaw cycles. This leads to improved durability and longevity of the self-leveling layer. The improved flow and leveling properties make the application process much easier and faster, saving time and labor costs. By understanding each step, you can clearly visualize how RDP enhances the overall performance and reliability of your self-leveling compounds.

RDP plays a critical role across various types and performance grades of cement-based self-leveling compounds. In standard-grade compounds, RDP primarily enhances workability and adhesion, ensuring a smoother application and better bond to the substrate. For intermediate or "enhanced" compounds, a higher dosage of RDP improves flexibility and crack resistance, making them suitable for floors with moderate movement. In high-performance, premium-grade self-leveling compounds, RDP is used in conjunction with other additives to achieve exceptional strength, flexibility, and durability, making them ideal for demanding applications like commercial flooring or floors with underfloor heating. The versatility of RDP allows for tailored formulations to meet specific performance requirements, optimizing both cost and effectiveness.

Using Redispersible Polymer Powder offers many advantages in cement-based self-leveling compounds:

The polymer network formed by RDP increases the flexibility and impact resistance of the hardened compound.

ZOVAE specializes in providing high-quality Redispersible Polymer Powders designed to optimize the performance of cement-based self-leveling compounds. Our ZOVAE® RDP series offers a range of products tailored to meet the specific requirements of various applications. We've meticulously developed our RDPs to ensure superior performance and reliability.

| Product Name | Polymer Type | Solid Content | Minimum Film Forming Temperature (MFFT) | Key Features | Recommended Dosage |

|---|---|---|---|---|---|

| ZOVAE® RDP 5018N | VAE | ≥ 98% | +5°C | Excellent adhesion, good flexibility, improved workability | 1.0-3.0% |

| ZOVAE® RDP 9032H | VAE/VeoVa | ≥ 98% | +3°C | Enhanced adhesion to difficult substrates, superior crack resistance, excellent water resistance | 1.5-3.5% |

| ZOVAE® RDP 6045N | Acrylic | ≥ 98% | +10°C | High strength, excellent abrasion resistance, ideal for heavy-duty applications | 2.0-4.0% |

Choosing the right Redispersible Polymer Powder is crucial for achieving the desired performance in your cement-based self-leveling compounds. Consider the following factors when making your selection:

| Application Requirements | Recommended ZOVAE® RDP Product |

|---|---|

| Residential Flooring | ZOVAE® RDP 5018N: Offers a good balance of adhesion, flexibility, and workability for general-purpose applications. |

| Commercial Flooring | ZOVAE® RDP 5115N: Provides superior adhesion, crack resistance, and abrasion resistance for high-traffic areas and demanding environments. |

| Underfloor Heating | ZOVAE® RDP 6011N: Offers excellent flexibility and resistance to temperature fluctuations, ensuring long-term performance in floors with underfloor heating systems. |

| Repair Mortars | ZOVAE® RDP 6028N: Provides high strength and excellent adhesion to existing concrete surfaces, making it ideal for repairing damaged or uneven floors. |

| Fast-Setting Compounds | ZOVAE® RDP 5026N: Compatible with fast-setting cement systems, ensuring rapid strength development without compromising performance. |

| Problem | Solution with ZOVAE® RDP |

|---|---|

| Cracking in Self-Leveling Compounds | The polymer network formed by these RDPs increases flexibility and impact resistance, minimizing crack formation even under stress or movement. |

| Poor Adhesion to Substrates | Enhances the bond strength to a wider variety of substrates, including those with residual contamination. Proper surface preparation is still recommended for optimal results. |

| Insufficient Flow and Leveling | Improves the rheology of the wet mixture, promoting better flow and self-leveling characteristics. This reduces the need for manual adjustments and ensures a smoother, more even surface. |

Key Suggestion: For optimal performance, ensure thorough mixing of the RDP into the dry compound and avoid adding excessive water.

| Ordering Information | Details |

|---|---|

| Packaging | 25 kg multi-layer paper bags with polyethylene liner |

| MOQ | 1 metric ton |

| Lead Time | 7-14 days, depending on order quantity and product availability |

| Payment Terms | T/T, L/C |

| Shipping | Sea freight, air freight, or land transport |

| Sample Policy | Free samples available upon request. Contact our sales team to request a sample of the ZOVAE RDP product that best suits your needs. We encourage you to test our RDP in your formulation. |

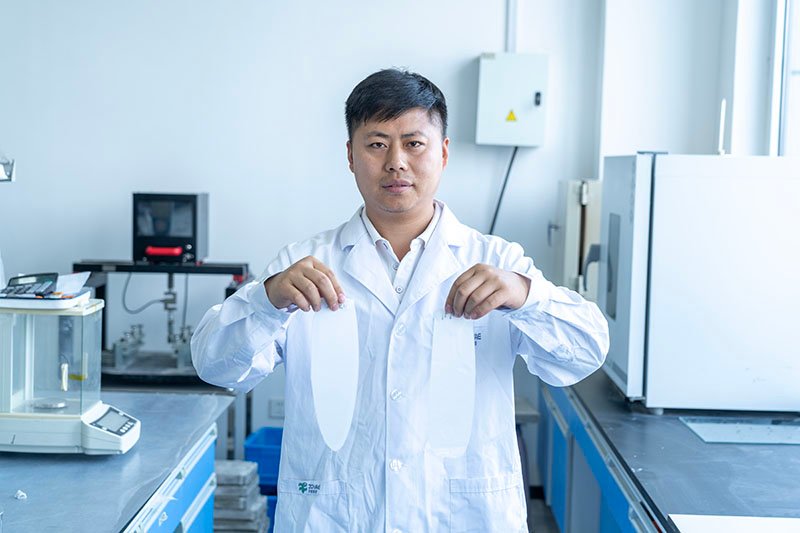

At ZOVAE, we maintain strict quality control standards throughout the manufacturing process to ensure consistent product performance. Our state-of-the-art production facilities are equipped with advanced monitoring and testing equipment. ZOVAE is committed to innovation, and our R&D team is constantly working to develop new and improved RDP products to meet the evolving needs of the construction industry. We invest heavily in research and development and collaborate with leading universities and research institutions to stay at the forefront of polymer technology.

Ready to improve your cement-based self-leveling compound performance? Contact ZOVAE today and request your free sample of ZOVAE® RDP. Let us help you create stronger, smoother, and more durable floors. With ZOVAE's ZOVAE® RDP series, you're not just buying a product; you're investing in the long-term quality and success of your flooring projects. Explore the benefits of redispersible polymer powder and experience the ZOVAE difference!

Don't hesitate to contact us for more information or to request a sample. Our experts are ready to assist you!

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.