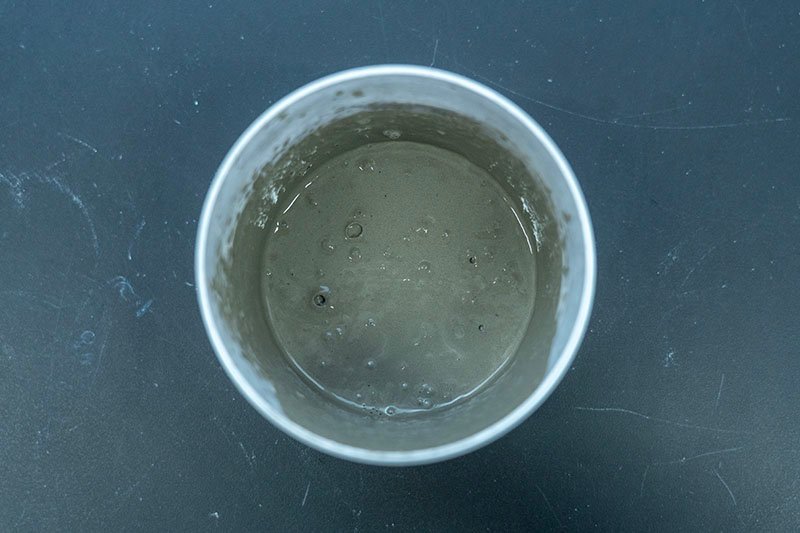

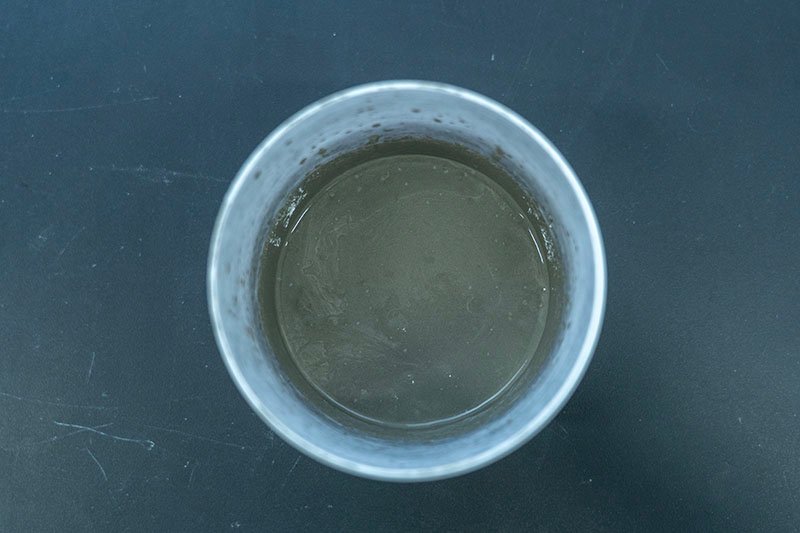

Are you battling pinholes, cracking, or weak adhesion in your repair mortar applications? These are common challenges faced by construction professionals, often stemming from entrapped air within the mortar mix. These seemingly minor issues can lead to significant problems, including reduced structural integrity, compromised aesthetics, and ultimately, costly rework. The solution? Powder defoamers for repair mortar. These specialized additives effectively eliminate air bubbles, resulting in stronger, smoother, and more durable repair mortar.

Powder defoamers are specialized additives designed to eliminate or significantly reduce air bubbles within repair mortar formulations. These bubbles, introduced during mixing and application, can compromise the mortar's performance. By disrupting the surface tension that stabilizes these bubbles, powder defoamers cause them to collapse and release, resulting in a denser, more homogenous mix. This simple action translates into a multitude of benefits, making powder defoamers an indispensable component of high-quality repair mortars.Powder defoamers are a cost-effective way to improve mortar strength, surface quality, and workability.

A powder defoamer for repair mortar is a dry-mix additive meticulously formulated to prevent the formation and persistence of air bubbles during the mixing and application phases. Think of it as a tiny army of bubble-busters. At its core, a powder defoamer typically comprises a blend of active defoaming agents, such as polyols, polysiloxanes, fatty alcohols, or polyethers, carefully dispersed within an inert carrier, like an inorganic mineral powder. This carrier ensures easy and uniform dispersion of the active ingredients throughout the dry mortar mix, preventing clumping and ensuring optimal performance. The powder form offers ease of handling and precise dosage control.

Imagine stirring sugar into your coffee. Without proper agitation, sugar clumps together. Powder defoamers work similarly, but in reverse! Air bubbles in mortar are stabilized by surface tension, like an invisible skin holding them together. Defoamers disrupt this surface tension in a two-pronged attack. First, the defoamer molecules migrate to the air-liquid interface of the bubble. Then, these molecules, often being hydrophobic (water-repelling), weaken the bubble’s structure. Simultaneously, they promote the coalescence of smaller bubbles into larger, more unstable ones that readily burst. This process, driven by the defoamer's chemical properties and its effect on surface tension, effectively releases the entrapped air, leading to a more compact and denser mortar matrix. This translates to fewer defects and enhanced overall performance.

Repair mortars aren't a one-size-fits-all solution. They come in various grades, each designed for specific applications and performance requirements. Powder defoamers play a crucial role in achieving the desired characteristics at each level:

In entry-level mortars for minor repairs, powder defoamers primarily prevent surface defects like pinholes, improving the aesthetic appearance and reducing the need for touch-ups.

For general-purpose repairs, defoamers enhance workability, making the mortar easier to apply and reducing the risk of cracking or delamination. They also contribute to improved adhesion.

Used for demanding structural repairs, these mortars require exceptional strength and durability. Powder defoamers are essential for maximizing compressive strength, minimizing internal weaknesses, and ensuring long-term performance under harsh conditions.

The inclusion of powder defoamers in repair mortar formulations offers a compelling array of benefits, directly impacting the quality, performance, and longevity of the repair work.

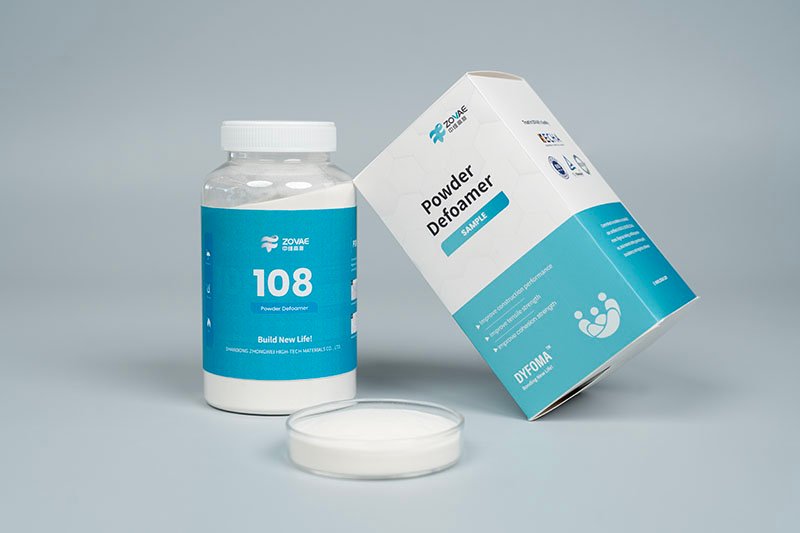

ZOVAE offers a range of high-performance powder defoamers specifically designed for repair mortar applications. Our products are meticulously formulated to deliver superior air release, enhanced workability, and improved durability.

| Parameter | ZOVAE Powder Defoamer 108 | ZOVAE Powder Defoamer 208 |

|---|---|---|

| Active Ingredient | Modified Polyol | Polysiloxane Blend |

| Appearance | White Powder | White Powder |

| Dosage (by weight) | 0.1% - 0.3% | 0.1% - 0.3% |

| Application | General Purpose | High Performance |

| Special Features | Excellent Air Release | Enhanced Durability |

| Benefits | Improves flow, reduces pinholes | Increases compressive strength, improves adhesion |

| Service Features | Free samples, global shipping, custom formulations | Free consultation, technical support |

ZOVAE's Powder Defoamer 108 excels in general-purpose repair mortars, providing excellent air release and improved flow. ZOVAE's Powder Defoamer 208, based on a polysiloxane blend, is tailored for high-performance applications, enhancing compressive strength and adhesion for demanding structural repairs. We offer free samples, global shipping, and custom formulation services to meet your specific needs. You can find more information about our powder defoamers for self-leveling mortar and repair mortar on our website: ZOVAE.com.

Selecting the appropriate powder defoamer for your repair mortar application depends on several factors, including the type of repair, the desired performance characteristics, and the environmental conditions. Consider the following:

| Condition | Recommendation | ZOVAE Product Suggestion |

|---|---|---|

| General Purpose Repair | Excellent Air Release, Good Workability | ZOVAE Powder Defoamer 108 |

| High Strength Repair | Maximum Compressive Strength | ZOVAE Powder Defoamer 208 |

| Demanding Applications | Superior Adhesion | ZOVAE Powder Defoamer 308 |

| Problem | Solution |

|---|---|

| Pinholes and Surface Defects | Using a powder defoamer ensures air is released during mixing, preventing these defects and leading to a smoother, more professional finish. |

| Weak Adhesion & Delamination | Powder defoamers help create a denser mortar, enhancing adhesion to the substrate and preventing delamination over time. |

| Reduced Compressive Strength & Durability | By eliminating entrapped air, powder defoamers maximize the density and strength of the mortar, resulting in a more durable repair. |

| Item | Details | Item | Details |

|---|---|---|---|

| MOQ | 1 Ton | Packaging | 25 kg bags |

| Lead Time | 7-14 days | Payment Terms | T/T, L/C |

| Shipping | Sea, Air | Sample Policy | Free samples available upon request |

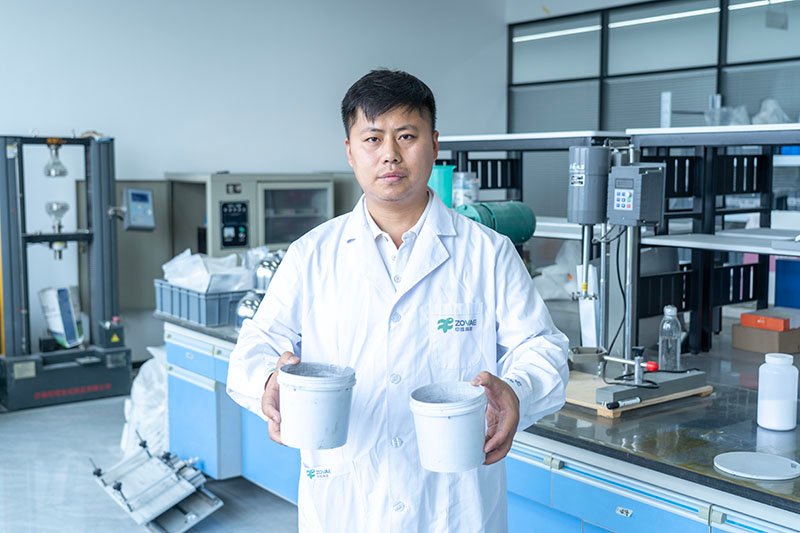

ZOVAE operates a state-of-the-art manufacturing facility equipped with advanced quality control systems. We adhere to stringent quality standards and conduct rigorous testing to ensure the consistent performance of our powder defoamers. Our dedicated R&D team is constantly innovating to develop new and improved defoamer formulations to meet the evolving needs of the construction industry. We utilize advanced analytical equipment and pilot-scale production lines to develop cutting-edge solutions.

In conclusion, powder defoamers for repair mortar are essential additives for achieving superior results. They enhance strength, improve workability, and ensure long-term durability. If you're looking for a reliable solution to improve your repair mortar, consider using ZOVAE's high-performance powder defoamers. Ready to elevate your repair mortar performance? Contact ZOVAE today and request your free sample. Let us help you achieve stronger, smoother, and more durable repairs!

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.