Polycarboxylate superplasticizers (PCEs) are advanced chemical admixtures specifically designed to enhance the performance of cementitious materials. In the context of self-leveling compounds, PCEs act as powerful dispersants, separating cement particles and significantly reducing the water required to achieve the desired flow.

Think of it like this: imagine a crowded room; PCEs act as “social directors,” ensuring everyone has enough space to move freely and efficiently. This enhanced dispersion is crucial for creating smooth, level surfaces that are both strong and durable. According to research, PCEs are more effective than traditional superplasticizers due to their superior slump retention and water reduction capabilities

Are you struggling with self-leveling compounds that lack sufficient flow, crack easily, or fail to achieve the desired strength? Then, polycarboxylate superplasticizer (PCE) for Self Leveling Compounds (SLC) might be exactly what you need.

The effectiveness of PCEs in self-leveling compounds stems from their unique chemical structure and their ability to interact with cement particles. Here’s a six-step breakdown:

5. Water Reduction: By keeping cement particles well-dispersed, PCEs reduce the amount of water needed to achieve the desired flowability. Less water means a denser, stronger final product.

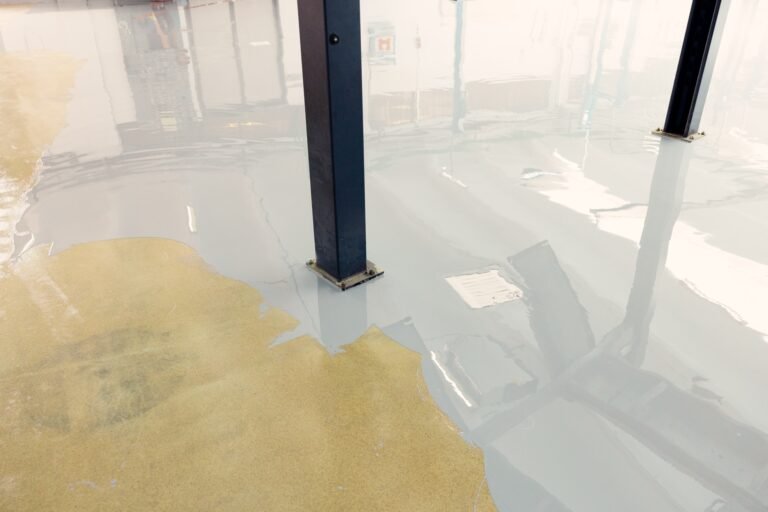

6. Enhanced Flow and Leveling: The combined effect of electrostatic repulsion, steric hindrance, and water reduction allows the self-leveling compound to flow easily and evenly, filling in gaps and irregularities to create a smooth, level surface.

Therefore, PCEs facilitate the homogeneous dispersion of cement particles, reduce water demand, and improve the overall workability of self-leveling compounds, resulting in superior performance and durability.

PCEs are versatile additives that can be tailored for various grades of self-leveling compounds, including:

PCEs improve the flowability and workability of standard compounds, ensuring easy application and a smooth surface finish.

PCEs enable rapid-setting compounds to achieve high early strength without compromising flow properties, accelerating project timelines.

These compounds leverage PCEs to achieve exceptional strength, durability, and resistance to cracking, ideal for demanding industrial and commercial applications.

Using polycarboxylate superplasticizers in self-leveling compounds provides a range of benefits that enhance the performance and durability of the final product. Here’s a detailed look at some key advantages:

| Property | Specification |

|---|---|

| Water Reduction Rate | ≥25% |

| Bulk Density | 600±100g/L |

| Active Ingredients | ≥90% |

| Moisture Content | ≤3% |

| Chloride Content | ≤0.05% |

| pH Value | 6.0-8.0 |

| Appearance | White powder |

| Main Features | High water reduction, excellent slump retention, enhanced workability |

ZOVAE offers a range of high-performance polycarboxylate superplasticizers specifically formulated for self-leveling compound applications. Our ZOVAE product, boasting exceptional slump retention and minimal air entrainment, guarantees superior water reduction efficiency. We are committed to providing solutions that meet the demands of modern construction.

We provide free samples, global shipping, and customized formulations to meet your specific requirements. Contact us today to discuss your project needs and explore how our PCE solutions can elevate the performance of your self-leveling compounds.

Selecting the appropriate PCE for your self-leveling compound application depends on several factors, including the type of cement used, desired flow properties, setting time requirements, and environmental conditions. Consider these recommendations:

| Condition | Recommendation |

|---|---|

| High Early Strength | POLLYFLEX™ 740 that promotes rapid hydration and early strength development. |

| Extended Workability | POLLYFLEX™ 790 with excellent slump retention to maintain workability over time. |

| Low Viscosity | POLLYFLEX™ 730 that provides high flowability without compromising stability. |

| High Temperature | POLLYFLEX™ 760, designed to perform well under elevated temperatures. |

| Specific Cement Type | POLLYFLEX™ 760 that is specifically formulated for use with the chosen cement type. |

Here are some common issues encountered when using self-leveling compounds and how PCEs can provide solutions:

To ensure optimal performance and safety when using ZOVAE PCE for self-leveling compounds, please follow these guidelines:

Key to Success: Always perform trial mixes to determine the optimal dosage and mixing procedure for your specific application. This ensures you achieve the desired performance characteristics for your specific project.

We make it easy for you to access our high-quality PCEs. Here’s what you need to know to place an order:

| Specification | Details |

|---|---|

| MOQ | 1 Ton |

| Packaging | 25kg bags or customized |

| Lead Time | 7-14 days |

| Payment Terms | T/T, L/C |

| Shipping Method | Sea, Air, or Land |

| Sample Policy | Free samples available |

As ZOVAE, we maintain strict quality control standards throughout the manufacturing process, ensuring consistent product performance. Our state-of-the-art R&D facilities enable us to develop innovative PCE formulations tailored to meet the evolving needs of the construction industry. We continuously invest in advanced equipment and technologies to enhance our product performance and sustainability.

Polycarboxylate superplasticizers are indispensable admixtures for achieving high-performance self-leveling compounds. By enhancing flowability, reducing water demand, and improving durability, PCEs enable the creation of smooth, strong, and long-lasting surfaces. For residential, commercial, or industrial applications, choosing the right polycarboxylate superplasticizer for self-leveling compounds is critical.

Ready to improve your self-leveling compound performance? Contact ZOVAE today and request your free sample to experience the difference firsthand. Let us help you achieve superior results with our advanced PCE technology and see why we are a trusted name in the industry!

Please leave your contact information, and Zovae’s sales team will provide you with dedicated service.