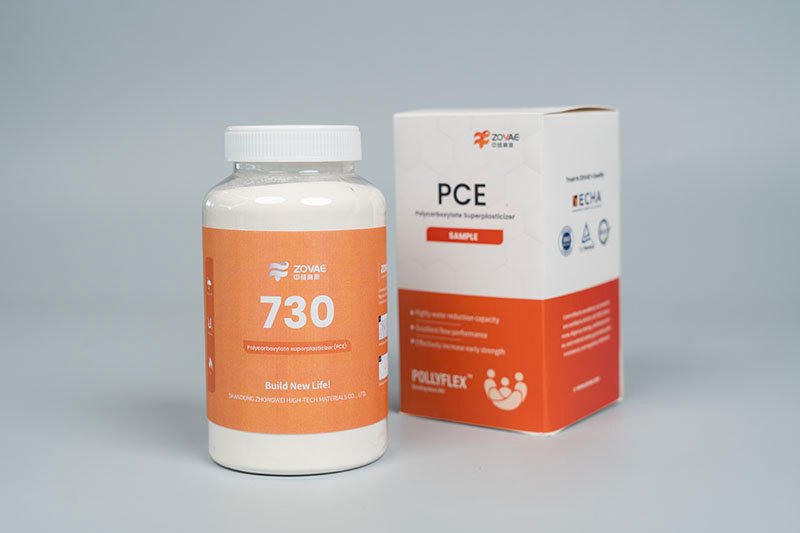

What is Polycarboxylate Superplasticizer (PCE)?

Polycarboxylate superplasticizer is a synthetic polymer specifically designed to act as a highly effective water reducer in concrete mixtures.

Imagine cement particles as tiny, irregularly shaped magnets that tend to clump together, hindering flow and requiring more water to achieve the desired consistency. PCEs work by adsorbing onto the surface of these cement particles, creating a steric hindrance effect. This means the long, branched polymer chains of the PCE create a physical barrier that prevents the cement particles from clumping together, allowing them to disperse uniformly in the mixture.

This improved dispersion significantly reduces the friction between particles, resulting in a highly workable and flowable concrete mix, even with a significantly lower water content. This lower water-cement ratio is the key to achieving higher strength and durability. As noted in research from Sancolo, PCEs are widely used in precast concrete for their ability to greatly enhance workability.