Fast-Setting Gypsum Plaster? Use Retarders for Control

Are you struggling with gypsum plaster setting too quickly? Do you find yourself constantly battling to achieve a smooth, workable finish before the plaster hardens? Then a gypsum retarder might be exactly what you need. At ZOVAE, we understand these challenges, and that’s why we offer solutions like our flagship product, ZOVAE to help you achieve superior results.

What is a Gypsum Retarder for Gypsum Plaster?

A gypsum retarder is an additive specifically formulated to slow down the hydration process of gypsum plaster. Think of it as a “pause button” for the setting reaction. Chemically, it works by interfering with the formation of calcium sulfate dihydrate crystals, the building blocks of hardened gypsum. This interference extends the working time of the plaster, giving you more opportunity to achieve a flawless finish. A gypsum retarder is an additive specifically designed to slow down the setting time of gypsum-based plasters, making it easier to achieve a smooth and workable finish, especially under hot or dry conditions where plaster can set too quickly.

How Does it Work?

Imagine gypsum plaster as a fast-moving train. The train (the setting process) needs to reach its destination (a hardened state) within a limited timeframe. A gypsum retarder acts like a temporary braking system.

- Mixing: The retarder, available in powder or liquid form, is mixed into the water used to prepare the gypsum plaster.

- Inhibition: Once added, the retarder inhibits the formation of calcium sulfate dihydrate crystals. It does this by adsorbing onto the surface of the gypsum particles, preventing them from readily reacting with water. Gypsum retarders work by inhibiting the chemical crystal formation that causes the plaster to harden, thereby extending the set time and allowing more time for proper application and finishing.

- Extended Work Time: This inhibition slows down the crystal growth, extending the "open time" or working time of the plaster. You now have more time to mix, apply, level, and smooth the plaster.

- Controlled Setting: Eventually, the retarder's effect diminishes, and the hydration process resumes. The plaster sets and hardens normally, but with a delay that allows for proper application and finishing.

- Enhanced Performance: The extended working time leads to better bonding between layers, reduced stress during setting, and a smoother, more durable final product.

- Environmental Adaptation: The retarder counteracts the effects of high temperatures and low humidity, conditions that accelerate the setting of gypsum and make it difficult to work with.

Applications Across Gypsum Plaster Grades

Gypsum retarders are versatile and can be used across various types of gypsum plaster:

Conventional Gypsum Plasters

These are standard plasters used for general wall and ceiling applications. Retarders provide extended working time, especially in warmer climates.

Lime Finish Plasters

Lime-based plasters benefit from retarders, as they improve workability and reduce the risk of cracking during the slower setting process.

Veneer Plasters

Setting-Type Joint Compounds

Key Benefits of Using Gypsum Retarders

The advantages of incorporating a gypsum retarder like ZOVAE SetControl into your plastering process are numerous:

Prolonged Setting Time for Enhanced Workability

- Increased working time, allowing for larger batches and more complex applications.

- Reduced waste due to premature setting.

- Easier to achieve a smooth, consistent finish.

Superior Surface Finish

- More time for leveling and smoothing, eliminating imperfections.

- Reduced risk of trowel marks and other surface defects.

- Improved aesthetics for a professional-looking result.

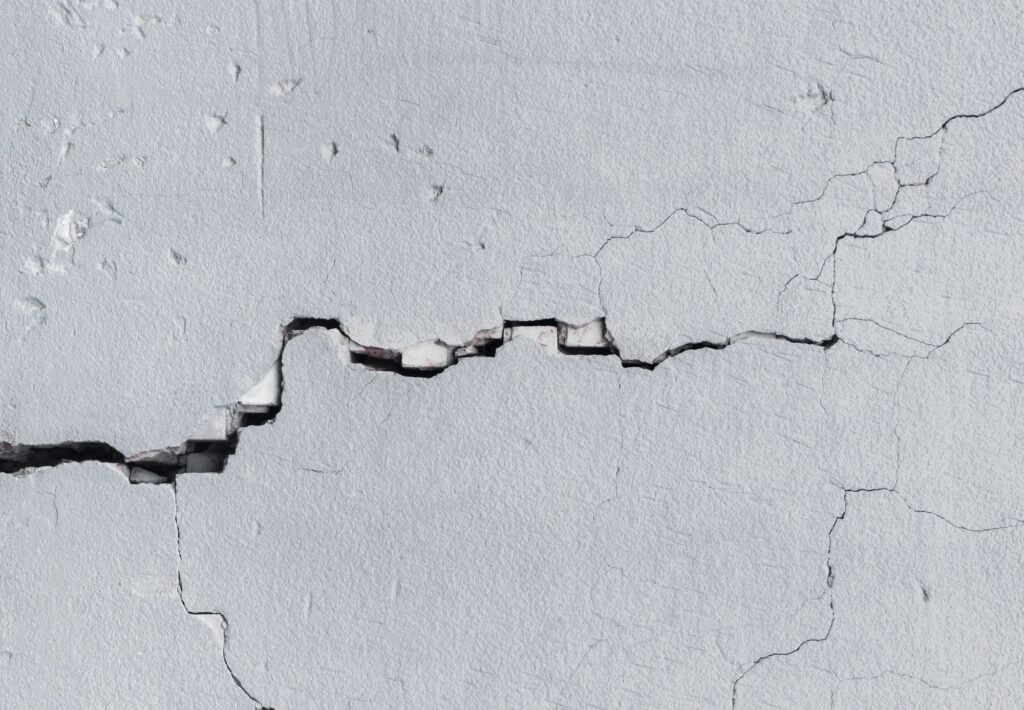

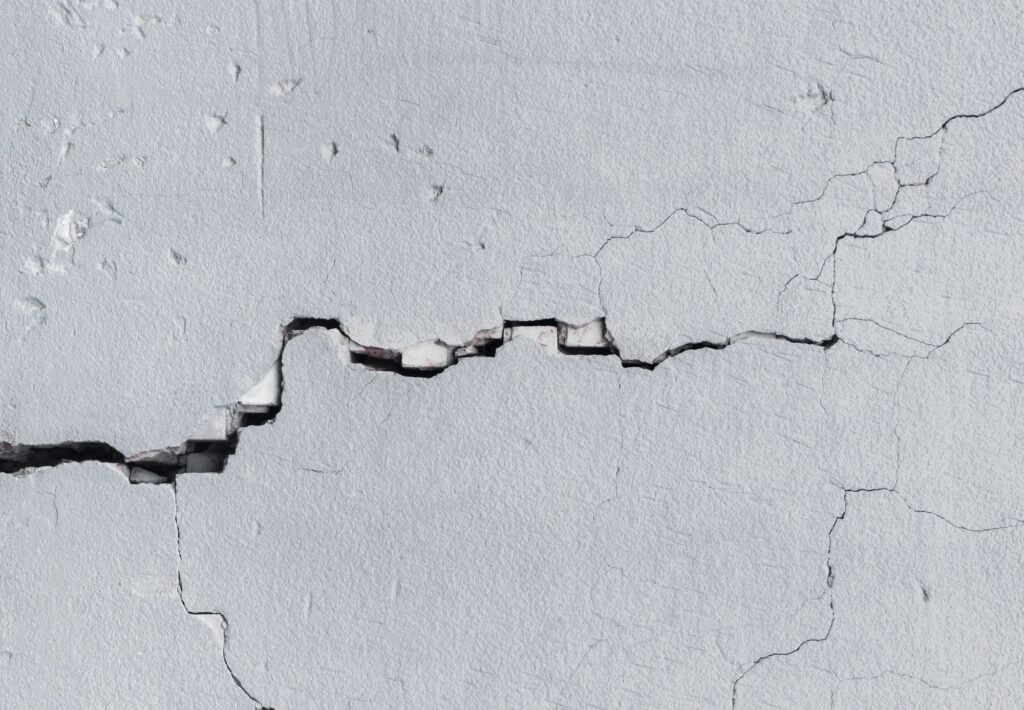

Minimized Cracking and Shrinkage

- Reduced early drying stresses, preventing surface cracks.

- Improved bond strength between layers of plaster.

- Enhanced durability and longevity of the plasterwork.

ZOVAE: Your Partner in Gypsum Plaster Solutions

At ZOVAE, we’re committed to providing high-quality gypsum retarders tailored to your specific needs. Our flagship product is specially formulated for consistent and reliable performance. Typical application involves mixing the retarder into the water used for preparing the gypsum plaster, with dosage adjusted based on the desired delay (often around 0.01–0.1% of the gypsum weight).

Prolonged Setting Time for Enhanced Workability

- Precise Set Time Control: Easily adjust the dosage to achieve the desired setting time, from 30 minutes to several hours.

- Consistent Performance: Ensures predictable and reliable results, batch after batch.

- Improved Workability: Enhances the plasticity and smoothness of gypsum plaster.

- Reduced Cracking: Minimizes the risk of surface cracks and shrinkage.

- Global Availability: ZOVAE is available for shipping worldwide, with technical support and application guidance.

We also offer free samples and custom formulation services to help you optimize your gypsum plaster mixes.

Choosing the Right Gypsum Retarder

Selecting the appropriate gypsum retarder depends on several factors:

Type of Plaster

Consider the specific type of gypsum plaster you are using (conventional, veneer, lime finish, etc.).

Ambient Conditions

Hot and dry conditions require a higher dosage of retarder.

Desired Set Time

Determine the amount of set time extension needed based on your application and skill level.

Application Thickness

Common Problems & Solutions

| Problem | Solution |

|---|---|

| Plaster sets too quickly. | Increase the dosage of gypsum retarder, ensuring it is thoroughly mixed into the water. |

| Surface cracking appears. | Use a gypsum retarder to reduce early drying stresses. Ensure proper mixing and application techniques. |

| Difficulty achieving a smooth finish. | Employ a gypsum retarder to extend the working time, allowing for more time to level and smooth the plaster. Use appropriate tools and techniques for finishing. |

Instructions for Use

- Prepare the Water: Measure the required amount of water for your gypsum plaster mix.

- Add Retarder: Add the appropriate dosage of ZOVAE SetControl to the water and mix thoroughly until dissolved.

- Mix Plaster: Gradually add the gypsum plaster to the water while mixing continuously until a smooth, lump-free consistency is achieved.

- Apply Plaster: Apply the plaster to the surface according to standard industry practices.

Success Tip: Always conduct a small-scale test mix to determine the optimal dosage of retarder for your specific conditions.

Ordering Information

| Specification | Details |

|---|---|

| Minimum Order Quantity (MOQ) | 1 metric ton |

| Packaging | 25kg bags or as per request |

| Lead Time | 7-14 days after order confirmation |

| Payment Terms | T/T, L/C |

| Shipping Options | Sea, Air, or Land |

| Sample Policy | Free samples available upon request |

ZOVAE: Quality and Innovation

Ready to Achieve a Superior Gypsum Plaster Finish?

Don’t let fast-setting plaster compromise the quality of your work. Contact ZOVAE today to request a free sample of ZOVAE and discover the difference a high-quality gypsum retarder can make. Let us help you optimize your plaster mixes and achieve exceptional results. Contact us to know more.